Laboratory

The laboratory was created to meet the widest possible range of needs of our clients.

Find out how we can help you

WHAT WE DO?

We have the appropriate knowledge, experience, and equipment to provide you with a full range of laboratory services. The analyses performed are also within the scope of ISO 9001:2015 certification, so you can be sure of the quality and reliability of the conducted research.

Laboratory

TESTS ACCORDING TO INTERNATIONAL STANDARDS

In the quality coating tests, we rely on Qualicoat, Qualisteelcoat, and Qualanod standards, as well as international ISO norms.

Qualicoat

- Coating thickness test according to ISO 2360

- Dry and wet adhesion tests according to ISO 2409 (cross-cut method)

- Impact resistance test according to ISO 6272

- Hardness test according to Buchholz method ISO 2815

- Gloss degree measurement at a 60º light incidence angle according to ISO 2813

- Polymerization test for powder and liquid coatings

- Degree of aluminum etching after surface preparation

Qualisteelcoat

- Coating thickness test according to ISO 2808

- Dry and wet adhesion tests according to ISO 2409 (cross-cut method)

- Gloss degree measurement at a 60º light incidence angle according to ISO 2813

- Neutral salt spray (NSS) resistance test according to ISO 9227

Qualanod:

- Anodic coating thickness test according to ISO 2360

- Anodic coating sealing quality test by mass loss measurement according to ISO 3210 (method 2)

- Anodic coating sealing quality test by absorption capacity determination (color spot test according to ISO 2143)

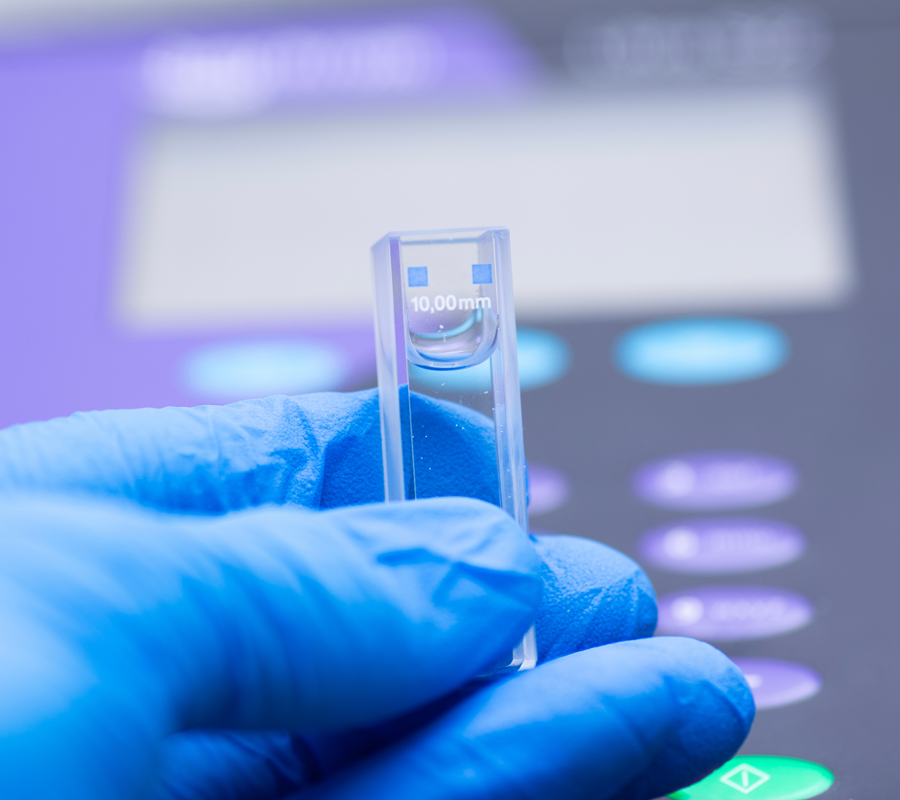

Sample testing of process baths

Our clients have the opportunity to periodically provide us with samples of process baths, usually to check compliance with their own results. The tests are free of charge and are part of our standard service care.

Coating

quality testing

Upon request, we conduct tests on the quality of paint and anodic coatings. Our testing methods are based on the requirements of Qualicoat, Qualanod, GSB, and relevant international standards.

Salt

We have our own salt spray chamber. Each of our clients has the opportunity to conduct periodic free tests along with a full report.

Coating

defect identification

Utilizing the resources of our laboratory and our partners, we help identify the causes of defects in paint and anodic coatings.

Technological

projects

For newly emerging investments, we offer the preparation of a full technological project for the chemical surface treatment stage.

Specialized

training

We train line operators, laboratory technicians, and management staff. The training can be conducted at our laboratory or at the client’s premises.

Dowiedz się więcej

Skontaktuj się z nami

Biuro

e-mail

biuro@chemly.pl

telefon

(42) 676 26 45

adres

92-332 Łódź, Al. Piłsudskiego 143, bud 58